Precision Solutions by Mainstream Waterjet, LLC

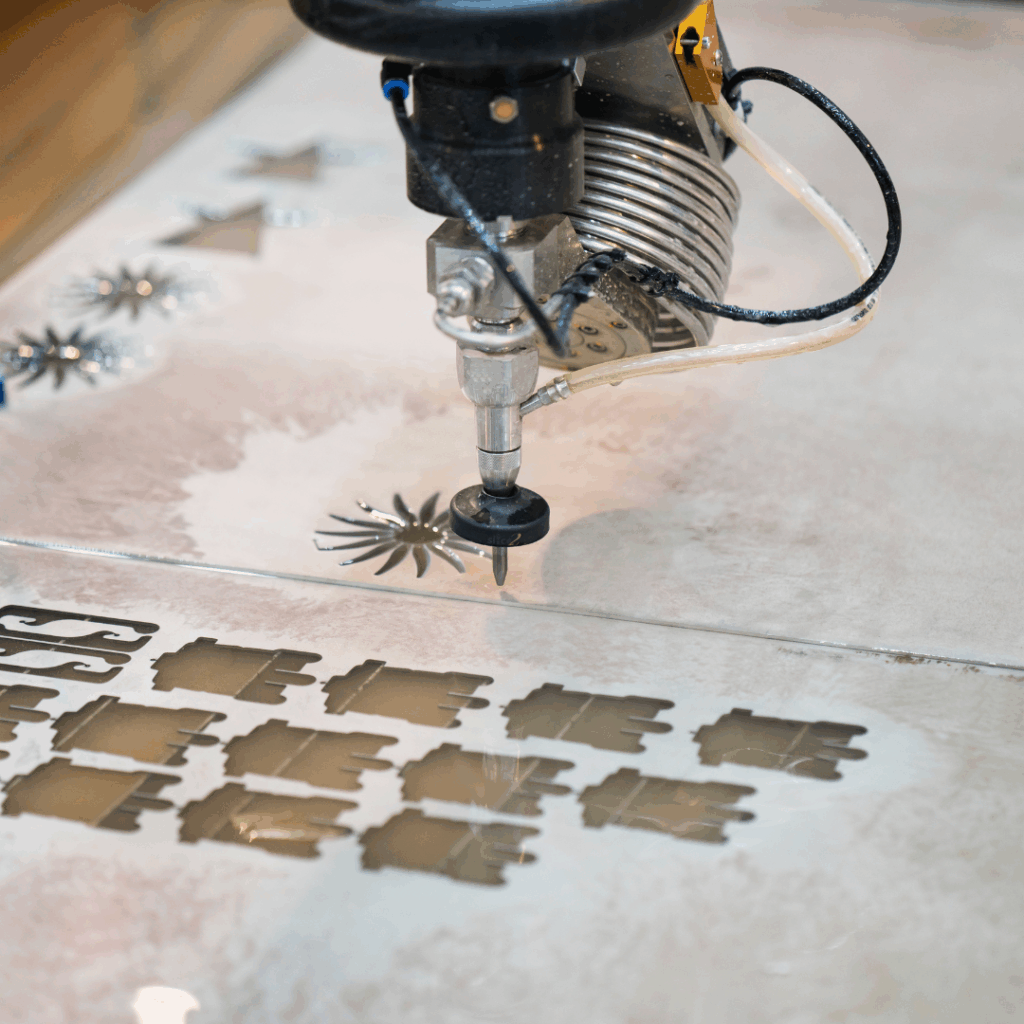

Our advanced 5-axis abrasive waterjet cutting and machining capabilities open up high-precision, cost-effective manufacturing for demanding industries. With over 35 years of experience, Mainstream delivers parts that meet rigorous tolerances, complex geometries, and rapid turn-times.

Why Choose Waterjet at Mainstream?

- Thick-section capability – We can cut material up to 24″ thick, enabling heavy-duty components that many job-shops can’t handle.

- Tight tolerances – Hold precision down to ± 0.001″, ensuring parts meet your most exacting standards.

- 5-axis versatility – With a 240″ × 120″ work envelope and full 5-axis motion, we can handle weld-prep bevels, tubing/piping, formed tank heads, structural components, and more—reducing expensive secondary operations.

- No heat-affected zone (HAZ) – As opposed to conventional machining or thermal cutting, our waterjet process avoids recast layers, work-hardening and thermal stress—ideal for specialty metals and sensitive geometries.

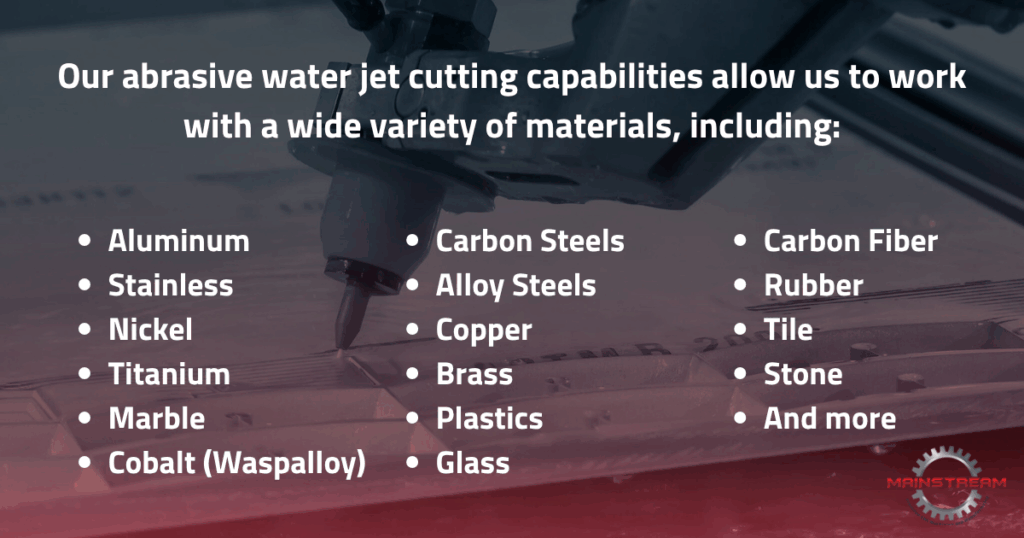

- Material diversity – From aluminum, stainless, nickel and titanium to carbon steels, copper, brass, plastics, stone, glass, carbon fiber and ceramics, we’re equipped to handle a broad range of substrates.

Our Process & Benefits to You

-

- Near-net cutting – We often waterjet-cut components to near-net shape, reducing the volume of machining required and significantly shortening cycle time.

- Streamlined workflow – Since the waterjet and subsequent machining are done in-house, you avoid outsourcing delays, hand‐offs, and added logistics.

- Cost and lead-time advantages – Better material utilization, fewer secondary processes, and consolidated fabrication mean lower component cost and faster delivery.

- Quality assurance built-in – We operate under AS9100D and ISO 9001:2015 management systems, and we are ITAR registered—so quality, traceability and documentation are handled to rigorous standards.

Ideal for These Applications & Industries

- Aerospace & defense (structural components, armor plate, honeycomb sandwich structures)

- Automotive (hoods, brackets, prototypes, tooling)

- Medical devices (exotic alloys, precision parts, non-thermal sensitive materials)

- Power generation (turbine components, large structural parts)

- Stone, tile, plastics and composite markets (glass, marble, carbon-fiber)

When you’re sourcing precision components, you want a partner, not just a vendor. At Mainstream, we combine advanced equipment, deep materials expertise, and full in-house capabilities under one roof—so you gain:

- Fewer vendors to manage

- Fewer hand-offs, less risk, smoother logistics

- Faster time-to-market

- Parts that meet spec right out of the gate

Let us help you shorten lead-time, reduce cost and improve quality—contact us today.