Mainstream provides safe, reliable, and high-performance components using advanced waterjet, CNC, and Swiss machining.

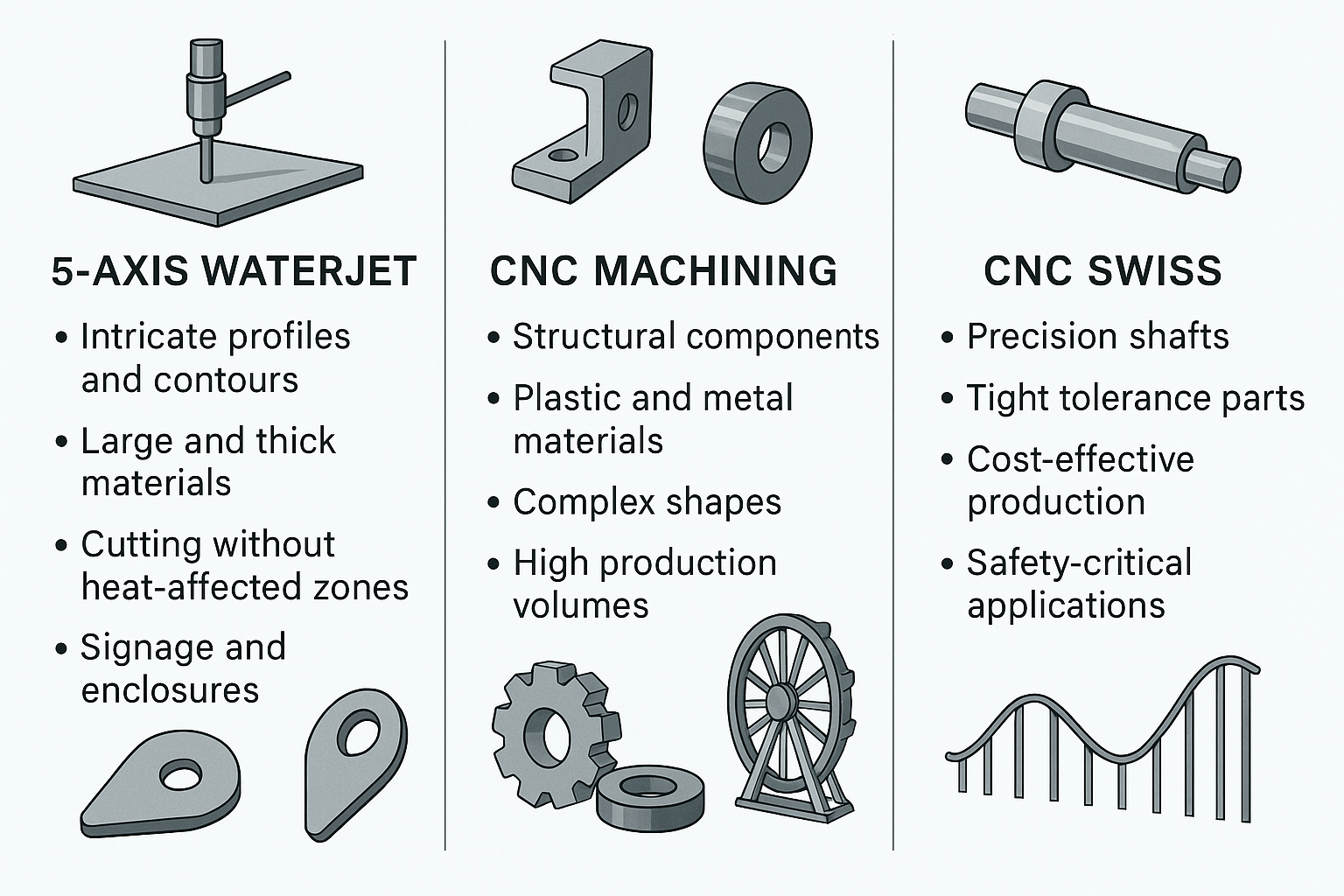

Amusement rides demand the highest levels of structural integrity, durability, and safety — and that starts at the component level. At Mainstream, we leverage our deep expertise in 5-axis waterjet cutting, CNC machining, and CNC Swiss machining to deliver complex parts that meet the rigorous demands of the amusement ride sector.

Rides are built with massive dynamic and static loads, exposed to varying environmental conditions, and must maintain safety margins decades into service. That’s why every part must be manufactured with exacting tolerances, consistent surface quality, and robust materials — no shortcuts.

Why Mainstream Is the Right Partner for Ride Manufacturers

Zero-heat cutting with waterjet

Our cold-cut waterjet process is ideal for cutting high-strength steels, stainless hardware, or specialty alloys used in ride structures — without creating heat-affected zones or warping.

Complex geometries with CNC / Swiss

Many ride components—such as actuation arms, interface brackets, bearings housings, precision pivots—require tight tolerances and smooth finishes. Our CNC and Swiss machining capabilities meet those demands consistently.

Scalable production, repeatability, and traceability

We support both low- and high-volume runs, with full process documentation, inspection reporting, and quality controls to ensure every part is identical and within specs.

Materials know-how

Whether your application uses structural steel, aluminum alloys, stainless grade materials, or specialty metals, we maintain the materials knowledge and equipment setups to optimize cut quality and throughput.

Industry compliance & safety focus

Safety is non-negotiable in amusement ride manufacturing. Our internal quality systems, inspection regimes, and best practices support the creation of parts that feed into safety-critical assemblies.

What You Can Expect When You Partner with Us

- Exacting tolerances and high surface quality

- Efficient lead times for prototypes to full production

- A collaborative, responsive engineering and operations team

- Full documentation and inspection packages

- Cost-effective, optimized machining processes

Let Mainstream be your trusted partner in creating the high-precision parts that keep amusement rides safe, reliable, and memorable.