Expert Manufacturing at Mainstream Waterjet, LLC

We combine advanced CNC machining capabilities with over 35 years of manufacturing experience to deliver precision components for complex applications. From prototypes to full production runs, Mainstream Waterjet offers a high-quality, turnkey solution for demanding industries.

Why Choose Our CNC Machining Services?

- Comprehensive machining workflow – We integrate CNC milling and turning with upstream near-net-shape cutting (via our waterjet services) to reduce machining time, cost and handling.

- High versatility in production volume – Whether you need short-run prototypes or high-volume runs, our machines are ready to scale.

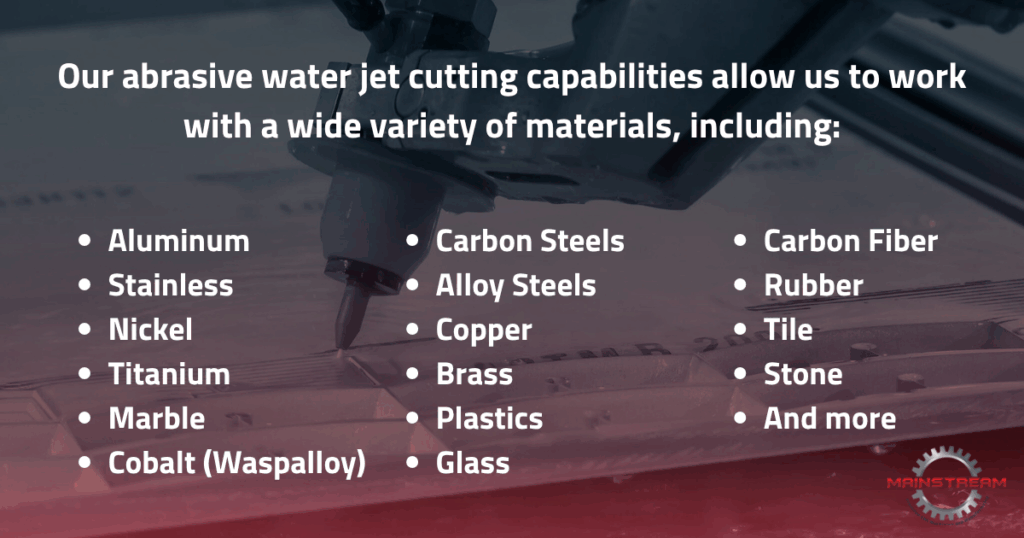

- Broad material capability – We work with aluminum, stainless steel, nickel alloys, titanium, cobalt (Waspalloy), carbon and alloy steels, copper, brass, plastics, glass, carbon fiber and more.

- Quality & compliance you can trust – AS9100D and ISO 9001 certified, and ITAR registered. These credentials reflect our dedication to rigorous documentation, traceability and reliability.

Our CNC Machining Process & Benefits for You

-

- Design review & feasibility – We start by analyzing your part drawing or model for optimal fabrication strategy, including whether near-net cutting (waterjet) then machining is best.

- Near-net shaping to reduce work – By waterjet-cutting material to near-net shape first, we minimize machining cycle time and reduce material waste—delivering savings in cost and time.

- Precision machining – Using state-of-the-art CNC equipment, we finish, bore, tap, mill, and turn with tight tolerances and complex features for high-performance applications.

- Inspection & documentation – Every part is inspected against your specifications; we deliver full documentation, traceability and compliance as required by regulated industries.

- Turnkey delivery – With our integrated services and one-stop-shop mindset, you gain fewer vendors, streamlined logistics, faster lead-times and higher consistency.

Ideal for These Applications & Industries

- Aerospace & defense (structural components, armor plate, honeycomb sandwich structures)

- Automotive (hoods, brackets, prototypes, tooling)

- Medical devices (exotic alloys, precision parts, non-thermal sensitive materials)

- Power generation (turbine components, large structural parts)

- Stone, tile, plastics and composite markets (glass, marble, carbon-fiber)

When precision, reliability and cost-effectiveness matter, you want a manufacturing partner—not just a vendor. Choosing Mainstream means:

- One partner for cutting, machining and finishing

- Fewer hand-offs, simplified logistics

- Faster turnaround and predictable cost

- High-quality parts built to exacting standards

Let us help you accelerate your production, optimize part cost and deliver components that meet spec the first time. Reach out today.