Precision-Engineered for Defense Applications

At Mainstream, we specialize in delivering rugged, high-performance components for today’s most demanding tactical defense systems. Leveraging over 35 years of manufacturing excellence, our team combines advanced technologies with a sharp eye for quality—ensuring every part meets the rigorous standards of the defense sector.

Why Mainstream Is the Trusted Defense Supplier

Certified Compliance for Defense Contracts: We hold AS9100D and ISO 9001:2015 certifications, demonstrating our unwavering commitment to quality management. As an ITAR-registered and DDTC-compliant provider, Mainstream adheres to the strictest export control and confidentiality protocols.

Unmatched Material Versatility: Our 5-axis abrasive waterjet systems and CNC machines expertly process a wide range of defense-relevant materials—from exotic metals like titanium, nickel, and cobalt to armor-grade steels, composites, glass, and plastics.

Cold Cutting Advantage: By using abrasive waterjet cutting, we avoid heat-affected zones, stress, and distortion—crucial for maintaining the mechanical integrity of critical defense components like missile housings, sensor housings, and structural bases.

Tight Tolerances for High-Stakes Applications: Capable of achieving tolerances as fine as ±0.001″, and handling parts up to 24 “ thick within a 240”×120” envelope, our precision enables production of intricate components, such as pressure vessels and complex geometries.

Integrated Manufacturing Expertise

Abrasive Waterjet Cutting

- Ideal for cold cutting specialty armor plates, composite assemblies, and intricate defense applications without thermal distortion.

- We complement waterjet cuts with features like bevels and weld prep to streamline downstream fabrication.

CNC Machining & Swiss Turning

- Post-waterjet, parts undergo precision CNC milling or Swiss-turning to achieve final form with highest accuracy—reducing cycle time and cost.

- Our CNC Swiss lathes support small, complex, high-volume parts from tough defense-grade metals.

Excellence You Can Rely On

- Engineering Depth & Collaboration: From prototyping to full-scale production runs, we partner with your engineering team to refine designs, recommend optimal processes, and help you scale efficiently.

- Rapid Turnaround & Adaptability: Whether you require a single prototype or a high-volume defense contract run, our experience and scale allow agile response to changing timelines and quantities.

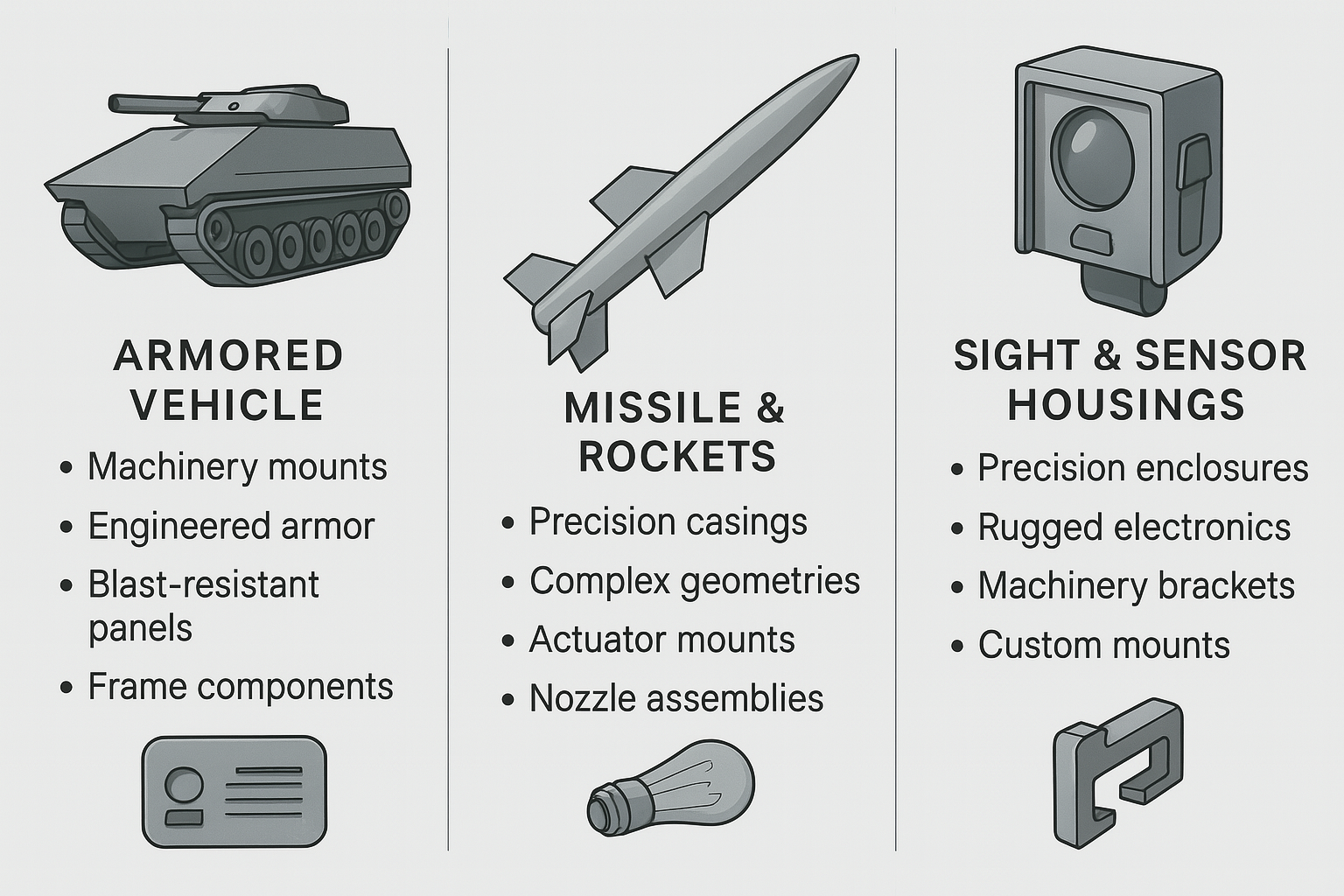

Applications in Defense

- Armored Structures: Hulls, blast-resistant panels, and structural frames

- Missile & Rocket Components: Casings, nozzle assemblies, actuator parts

- Sight & Sensor Housings: High-precision enclosures for rugged environments

- Custom Mounts & Brackets: Machinery and vehicle sub-assemblies

- Rugged Electronics & Shielding: Heat sinks, insulators, EMI enclosures

Ready to Power Your Next Defense-Level Project?

With AS9100 grade precision, full ITAR compliance, and unmatched material capability, Mainstream is your go-to partner for delivering critical defense components—on time and within spec. Contact us today to see how we can add precision, speed, and dependability to your defense manufacturing chain.