High-Volume, Multi-Axis Swiss Turning by Mainstream Waterjet, LLC

At Mainstream Waterjet, we combine advanced Swiss-style machining with deep materials expertise to deliver intricate, high-throughput components for demanding applications. With 35+ years of manufacturing experience and certified systems in place, we’re your partner for precision, repeatability and cost-effective production.

Why Choose Our CNC Swiss Services?

- Automated bar-feed Swiss-style turning – Our machines incorporate long-bar feeders (e.g., 12-foot bar intake) enabling continuous production of small-diameter, complex parts with minimal change-over.

- Intricate detail, high precision – Swiss-type lathes excel at tight tolerances, fine features, and multi-axis operations that reduce downstream machining and simplify assembly.

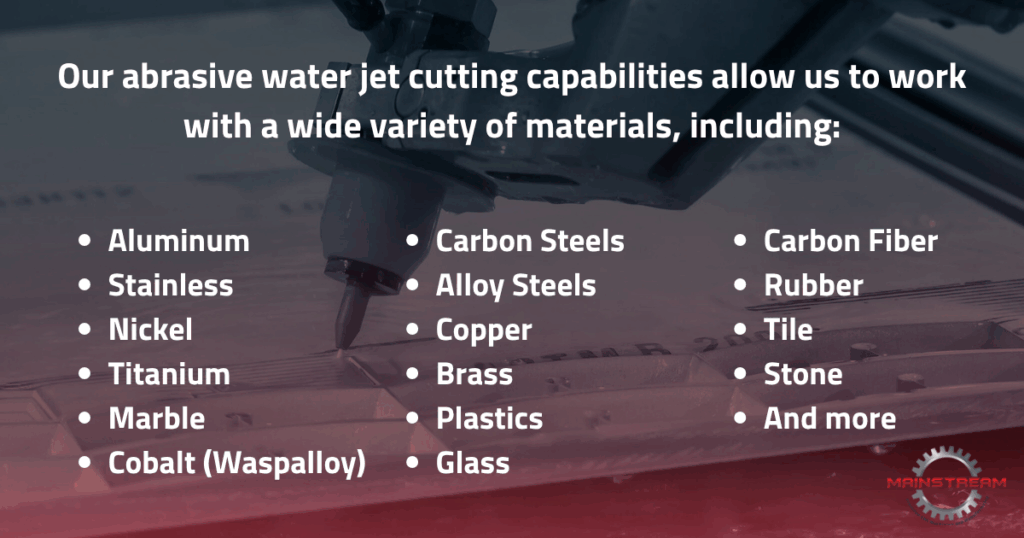

- Wide material & volume capability – Whether you need exotic alloys or high-volume commodity components, our Swiss-turning operations scale to meet your quantity, precision and material demands.

- Quality systems built-in – We carry AS9100D and ISO 9001 certification, as well as ITAR registration—ensuring traceability, documentation and control for regulated industries.

Our Swiss-Machining Process & Your Benefits

-

- Design and production review – We begin by analyzing your drawings and parts for Swiss-lathe suitability: feature complexity, diameter range, bar feed length, cycle times—and recommend the most efficient production strategy.

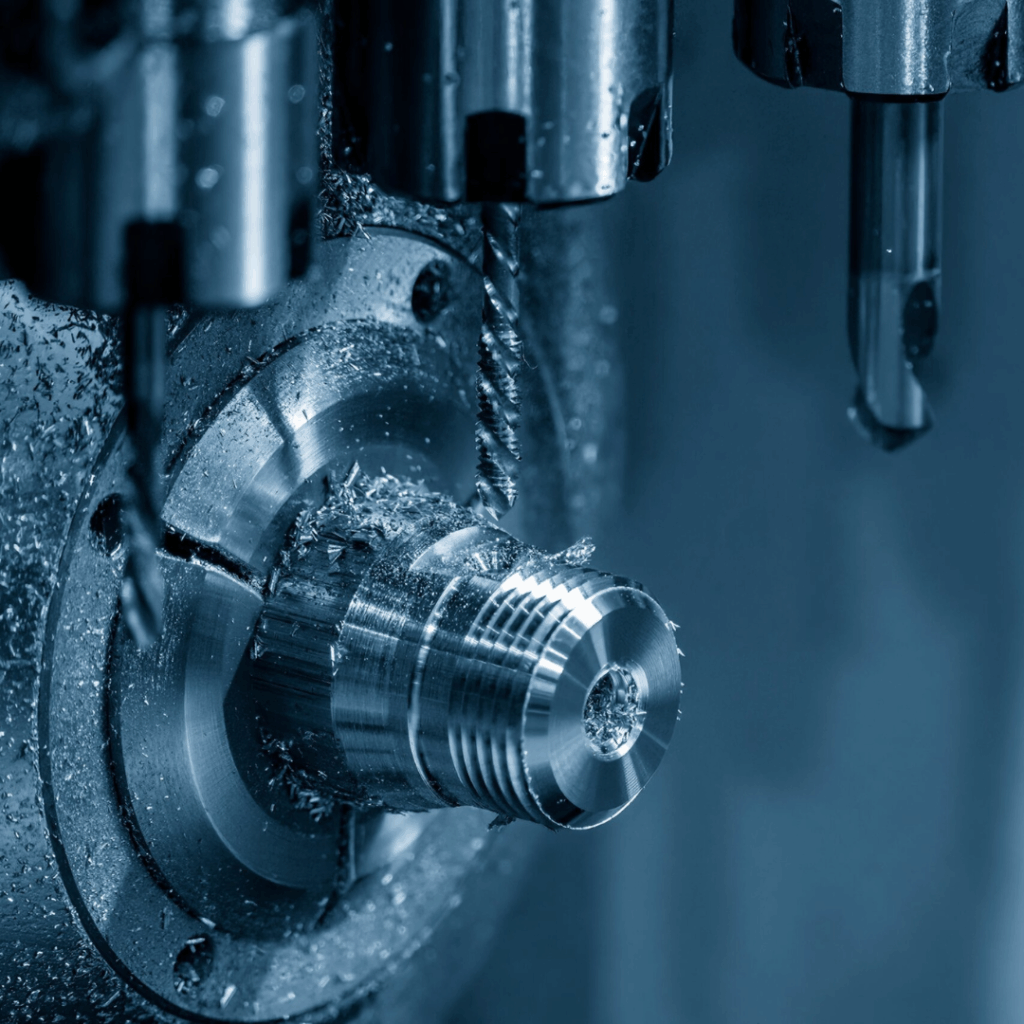

- Setup & bar-feed automation – Using long-bar feeders and automatic controls, we minimize downtime, reduce manual loading, and support continuous production runs.

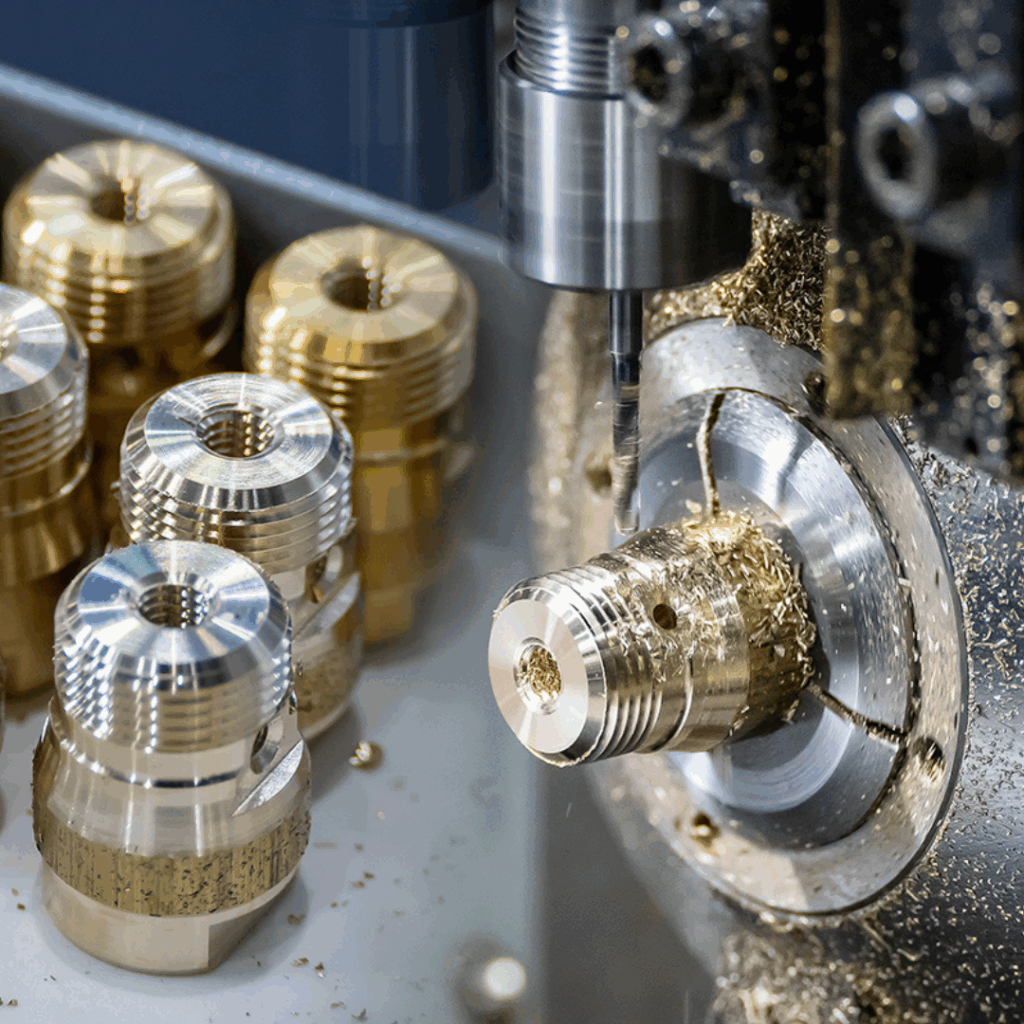

- Swiss-style turning & multi-axis operations – With sliding-head and fixed-head machines, multiple tooling stations, live tooling and sub-spindles, we perform turning, milling, drilling, tapping, and grooving in a single cycle.

- Inspection & documentation – Every lot is inspected to your tolerances; full documentation, traceability and reporting accompany your parts.

- Efficient delivery – Integration with our broader manufacturing services (waterjet cutting, CNC machining) means fewer vendors, tighter timelines, and consistent parts delivery.

Ideal for These Applications & Industries

- Aerospace & defense (structural components, armor plate, honeycomb sandwich structures)

- Automotive (hoods, brackets, prototypes, tooling)

- Medical devices (exotic alloys, precision parts, non-thermal sensitive materials)

- Power generation (turbine components, large structural parts)

- Stone, tile, plastics and composite markets (glass, marble, carbon-fiber)

When you’re sourcing precision, high-volume, miniature or complex components, the right manufacturing partner makes all the difference. With Mainstream you benefit from:

- One partner for Swiss turning, CNC machining and waterjet services

- Fewer hand-offs, simplified logistics and faster cycle time

- High precision, repeatability and traceable quality

- The ability to ramp production quickly and efficiently

If you’re ready to reduce cost, shorten lead time and improve component performance, let’s start the conversation.