12 Jun Swiss vs. Conventional CNC Machining: A Side-by-Side Look

Choosing the wrong machining method can lead to costly rework, missed deadlines, or components that fail under pressure. Here’s how to avoid that.

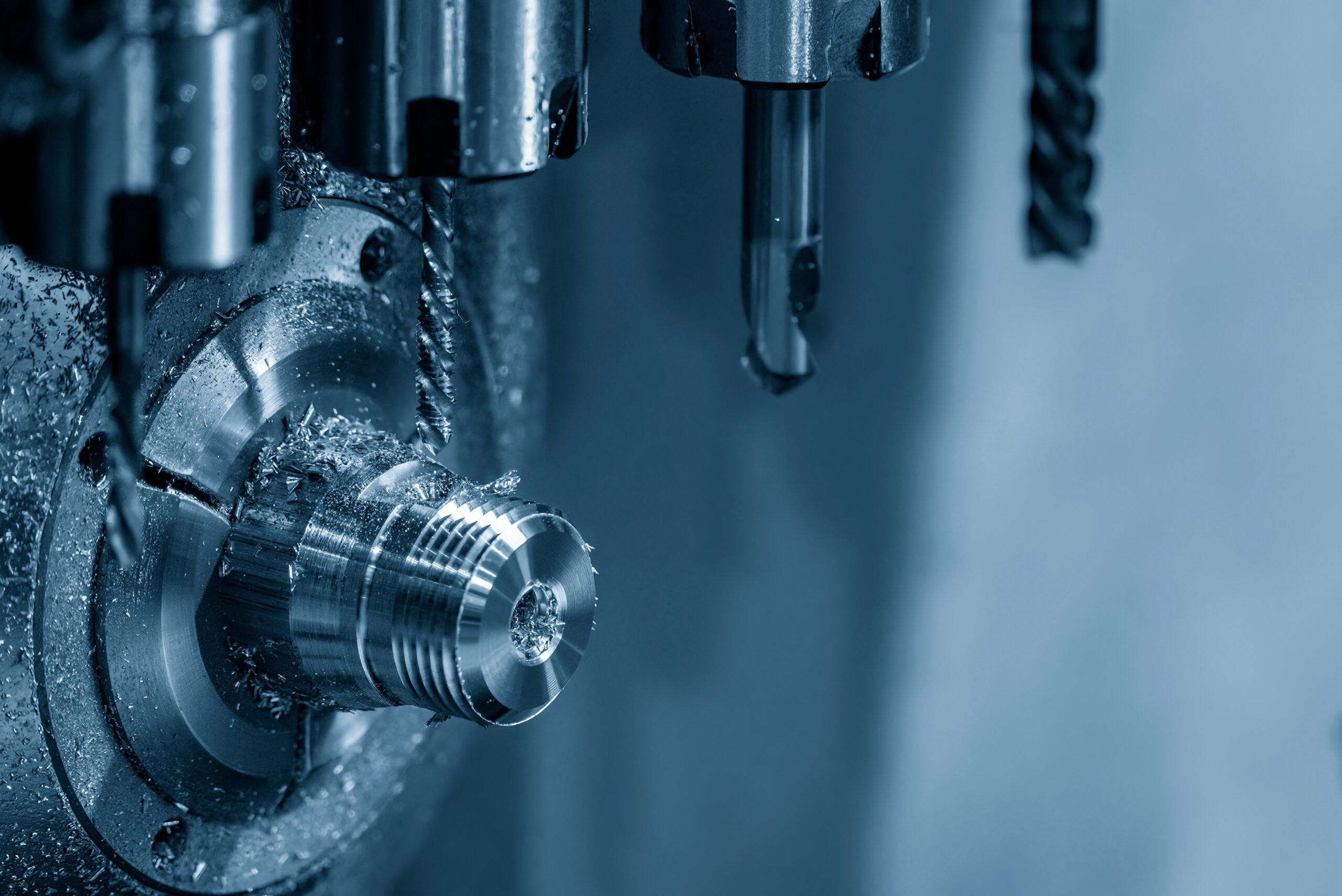

Two of the most common approaches in modern manufacturing are Swiss CNC machining and conventional CNC machining. While both deliver precision, they’re engineered for different types of components and production goals.

At Mainstream, we help you navigate those decisions with the right technology, expert insight, and proven processes.

What Is Swiss CNC Machining?

Swiss CNC machining uses a sliding headstock lathe, where the workpiece is supported close to the cutting tool. This added stability allows for extremely tight tolerances and precision on small, complex parts. Originally developed for Swiss watchmaking, this process is now a go-to in high-spec industries like aerospace, tactical defense, medical, and more.

At Mainstream, our Swiss CNC machines feature:

- Live tooling for complex geometries and cross-drilled features

- 12-foot bar feeders for lights-out, high-volume production

- Consistent precision in both low- and high-volume orders

- Expertise with specialty materials including titanium, nickel and cobalt alloys, stainless, aluminum, brass, and carbon steel

What Is Conventional CNC Machining?

Conventional CNC machining typically uses fixed-head lathes or milling machines to remove material. In lathe operations, the workpiece rotates while stationary tools shape the part. This method is ideal for larger, less intricate components or parts that don’t require micro-detailing.

With the right programming and tooling, conventional CNC machining can still achieve tight tolerances up to +/-.001”—making it a reliable choice for many industries and applications.

| Feature | Swiss CNC Machining | Conventional CNC Machining |

|---|---|---|

| Best For | Small, precise, complex parts | Larger, less complex components |

| Workpiece Stability | High (closer tool support) | Moderate |

| Volume Efficiency | Excellent for high-volume | Efficient for short to mid runs |

| Tooling | Live tooling for multi-axis cuts | Fixed tooling (multi-step) |

| Tolerance | Extremely tight | Tight, but less so |

| Industries | Aerospace, tactical defense, medical, electronics, pneumatic/hydraulic fittings | Automotive, industrial, construction |

When Should You Choose Swiss CNC Machining?

Swiss CNC machining is the right fit when:

- You need intricate, tight-tolerance components

- Your project involves high-volume production runs

- You’re using specialty materials including titanium, nickel and cobalt alloys, as well as stainless, aluminum, brass, and carbon steel

- Your parts include deep holes, slender geometries, or require complex, multi-feature machining

While Swiss CNC machining may have a higher initial setup cost, it saves money at scale. For high-volume runs, it delivers lower per-part pricing thanks to greater efficiency and reduced need for secondary operations.

Still not sure which method is best?

Our engineers can review your designs and recommend the most cost-effective machining process based on your material, tolerances, and production goals.

Partner With Mainstream For Precision Without Compromise

When precision is mission-critical, manufacturers across aerospace, medical, and defense industries turn to Mainstream. Why? Because we don’t just meet tolerances—we deliver consistent, high-quality results at scale.

Last year alone, we machined over 10,000 aerospace shims with zero scrap—a direct result of our closed-loop quality system and commitment to AS9100D and ISO 9001:2015 standards.

Whether you’re producing surgical implants, flight-critical components, or intricate turned parts, our Swiss CNC machining capabilities ensure repeatability, efficiency, and tight-tolerance accuracy—every time.

Have a part in mind?

Upload your CAD file for a free Design for Manufacturing (DFM) review and let our engineers help optimize your design for production.

No Comments